Odoo for Manufacturing: Proven Strategies To Manage Production

Odoo

5 MIN READ

October 8, 2024

![]()

Businesses, nowadays, continuously change to meet the rising demands, and market conditions, and increase business efficiency. To manage the production process, it is necessary to understand the right difference between success and failure. From small-scale manufacturers to large enterprises, opt for a platform that offers scalability and flexibility to adapt to the changing business environment.

If you want to reduce production costs, improve product quality, or optimize your manufacturing workflows, then Odoo is a specialized solution in the ERP industry. Proven strategies help you achieve your business goals to the right extent.

In this blog, we will explore how Odoo for the manufacturing industry helps to enhance performance. Not only this but we will also understand a complete Odoo manufacturing process, its advantages, its modules, and real-life examples in detail.

A Brief About – How Odoo for the Manufacturing Industry Works?

Odoo ERP, a platform specifically designed to meet the firm needs across industry verticals. Its modular approach assists companies in implementing the features they need, making it a highly customizable and scalable solution.

When we talk about Odoo for the manufacturing industry, it comes up with a range of tools and functionalities that automate the business process, improve workflow management, and ensure integration across departments. Leveraging the use of Odoo helps manufacturers manage everything from production planning to quality control in a centralized platform.

Odoo’s Role in Transforming Manufacturing Industry

Odoo is one such explorative platform in the manufacturing sector that centralizes and automates key processes. While compared with traditional manufacturing methods that lead to data inefficiencies, data silos, and errors, Odoo has taken the right place to overcome the challenges by providing a unified platform. From inventory management & production planning to control and maintenance, Odoo is there to make a wise decision and roadmap.

Odoo’s platform architecture allows manufacturers to integrate only the necessary utilities as per their needs and makes it a flexible and customizable solution. For a business, integration of operations or IoT devices for getting real-time data analysis, Odoo decreases the operations costs and accelerates the time-to-market for new products.

In addition, the open-source nature of Odoo enforces businesses to choose the modules and integrate with third-party applications to ensure scalability. The adaptability feature of Odoo evolves the manufacturing process and supports continuous innovation and improvement.

Case Study – Odoo Solution to Streamline Manufacturing and Inventory Management

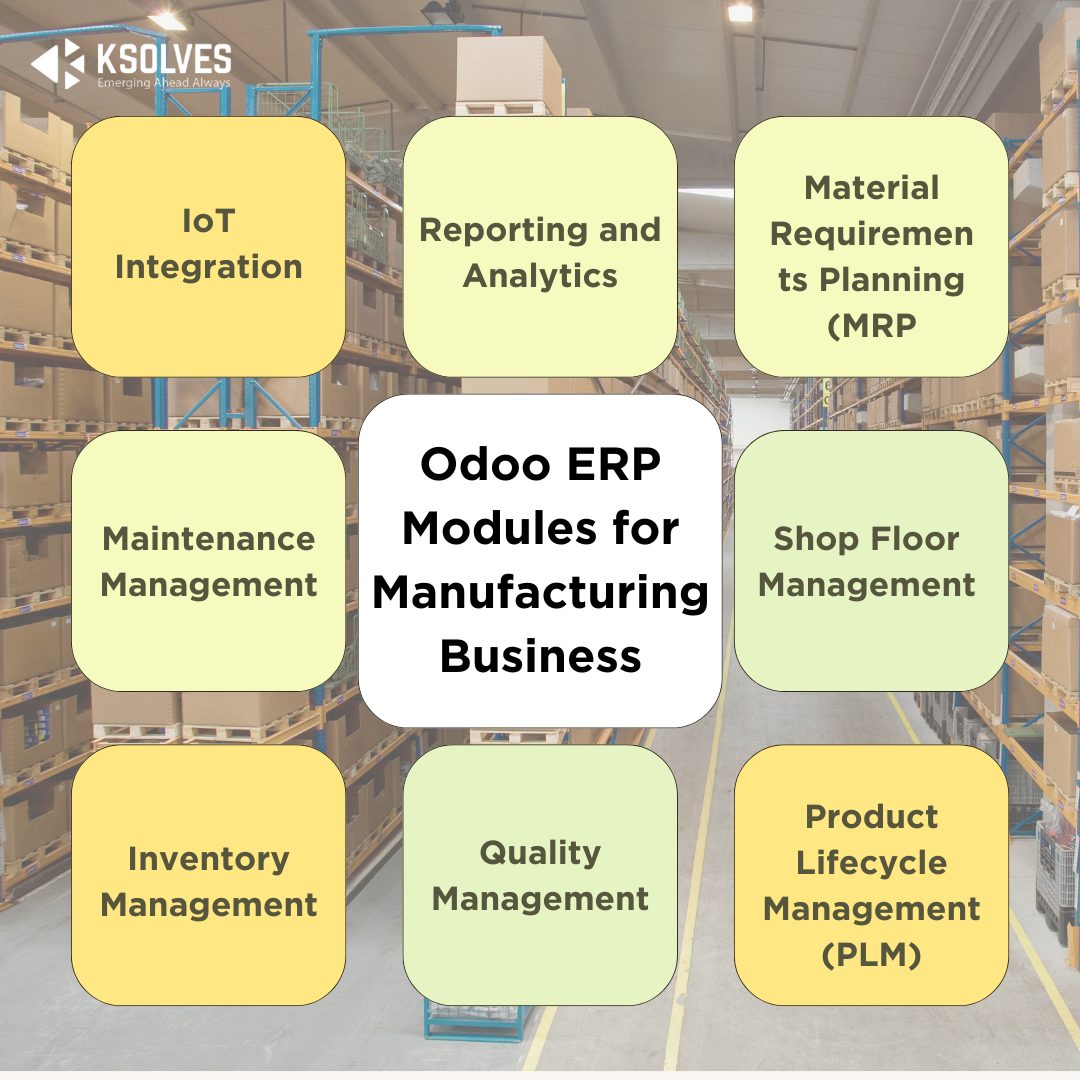

Essential Odoo Modules for Manufacturing Business

1. Material Requirements Planning (MRP)

The Odoo MRP module works on centrally managing the manufacturing process. It makes sure that all necessary materials are there for production, optimizes inventory levels, and focuses on planning production schedules efficiently. This reduces business downtime and ensures that production runs smoothly without disturbances.

2. Shop Floor Management

The Shop Floor module in Odoo ERP provides real-time visibility into the production process. All the managers can monitor work orders, track abductor efficiency, and identify bottlenecks in real time, allowing for quick adjustments to keep progress on track. It focuses on quick adjustments like:

- Scrap → is used to send components to a scrap location when they are found to be defective.

- Add Work Order → is used to add work order to the MO.

- Add Component → is used to add components to the MO.

- Open Backend MO→ opens the MO in the Manufacturing app.

3. Product Lifecycle Management (PLM)

The PLM module supports the entire lifecycle of a product, from initial design to final production. It facilitates collaboration among engineering, production, and quality teams, ensuring that everyone is aligned on product specifications and changes. This reduces errors and accelerates the development process.

Engineering Change Order (ECO) is a core aspect of PLM. ECO ensures the management of change requests in the product being used or the BOM variant for the betterment of the finished product.

The multi-level approval process ensures that the quality of the product is maintained with due diligence by each concerned department.

4. Quality Management

Ensuring product quality is crucial in manufacturing, and Odoo’s Quality module provides the tools to set up quality checks at different stages of production. It allows manufacturers to track non-conformities, implement corrective actions, and ensure that products meet the highest standards before they reach the market.

5. Inventory Management

Odoo’s Inventory module is designed to optimize stock levels, reduce carrying costs, and ensure that materials are available when needed. It integrates seamlessly with other modules, such as MRP and Purchasing, to provide a holistic view of inventory across the entire supply chain.

6. Maintenance Management

The Maintenance module helps in scheduling and tracking preventive maintenance activities, reducing unplanned downtime and extending the life of machinery. This proactive approach ensures that production remains uninterrupted and that equipment operates at peak efficiency.

7. IoT Integration

Odoo’s IoT module allows manufacturers to connect their machinery and devices to the ERP system, enabling real-time data collection and analysis. This integration supports predictive maintenance, improves decision-making, and enhances operational efficiency.

8. Reporting and Analytics

Odoo offers powerful reporting tools that provide insights into every aspect of the manufacturing process. Managers can generate detailed reports on production efficiency, inventory levels, and quality performance, helping them make data-driven decisions that improve operations. It offers some key reports like Allocation reports, Overall Equipment Effectiveness, and production analysis.

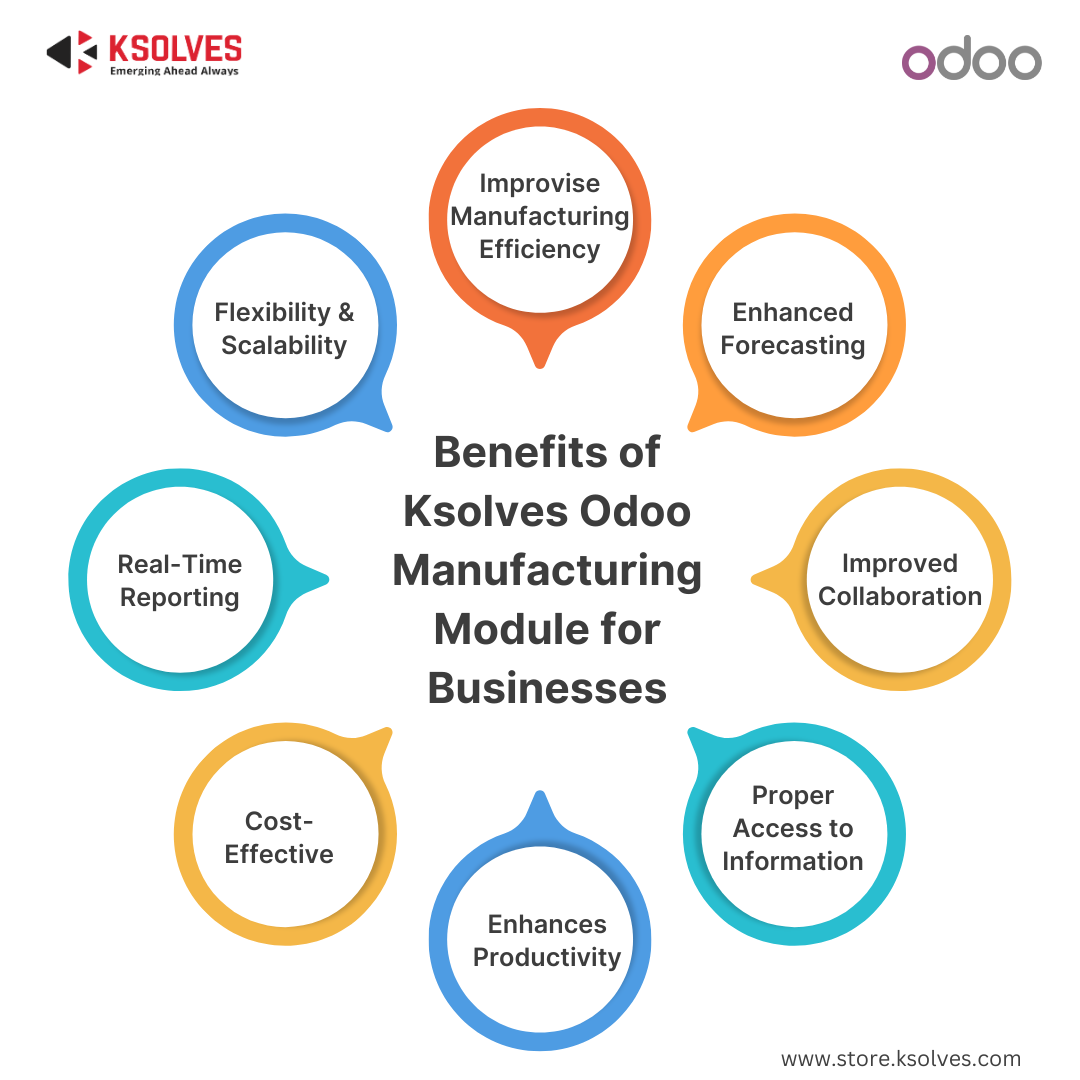

Benefits of Odoo Manufacturing Module For Businesses

1. Improvise Manufacturing Efficiency

Odoo Modules helps to automate manual tasks, integrate multiple business processes, and provide real-time insights that allow businesses to optimize their business operations. By leveraging the modules, users can maintain their business workflows, and manufacturers can reduce downtime, reduce errors, and increase productivity leading to a smooth production process.

2. Enhanced Forecasting

With advanced Odoo analytics and reporting tools, manufacturers can predict user demand accurately. It helps to assume the future inventory requirements, and material availability, and schedule the production. This solution makes sure that all the resources are allocated wisely, reduces waste, and improves the on-time delivery rates.

3. Improved Collaboration

Odoo’s integrated platform makes it easy for individuals to maintain procurement, production, or quality management teams. By centralizing the communication and making the data accessible to all the clients, Odoo makes sure that everyone works in the right sync and minimizes the risk of miscommunication and errors.

4. Proper Access to Information

Having access to real-time data is another advantage of Odoo. Managers can have quick access to all the vital information about the production status, inventory levels, quality metrics, and more. It improves visibility, enables faster decision-making and instant resolution of issues that prevent disturbances, and keeps the entire production chain running wisely.

5. Enhances Productivity

By utilizing the mentioned Odoo modules like Material Requirements Planning (MRP), Shop Floor Management, and IoT Integration, Odoo automates several time-consuming manual processes. This allows workers to focus on high-value tasks, enhance productivity, and make sure that the production targets are completed on time.

6. Cost-Effective

Another benefit of utilizing Odoo is its improvement in resource management, automation of repetitive tasks, and optimization of the entire supply chain. Even it reduces material waste, minimizes labor costs, and avoids excessive inventory to prevent loss.

However, the pricing model of Odoo makes sure that businesses only pay for those features that they utilize and make it a highly cost-efficient system as compared to others.

7. Real-Time Reporting

This Odoo platform offers a set of reporting tools that provide detailed insights into the entire production efficiency, product quality, resource usage, and financial performance. Manufacturers will get timely reports that help to identify improvement opportunities, optimize production strategies, and make informed decisions to bring the right business outcomes.

8. Flexibility

The Odoo’s modular architecture helps businesses to level up their operations as they grow. Odoo’s new modules and features can be added as per the need while expanding the production lines or adopting advanced technology like IoT. Its flexibility supports continuous business improvement and adaptability to make changes.

Read More – ERP for Furniture Industry: Streamline Operations and Overcome Challenges

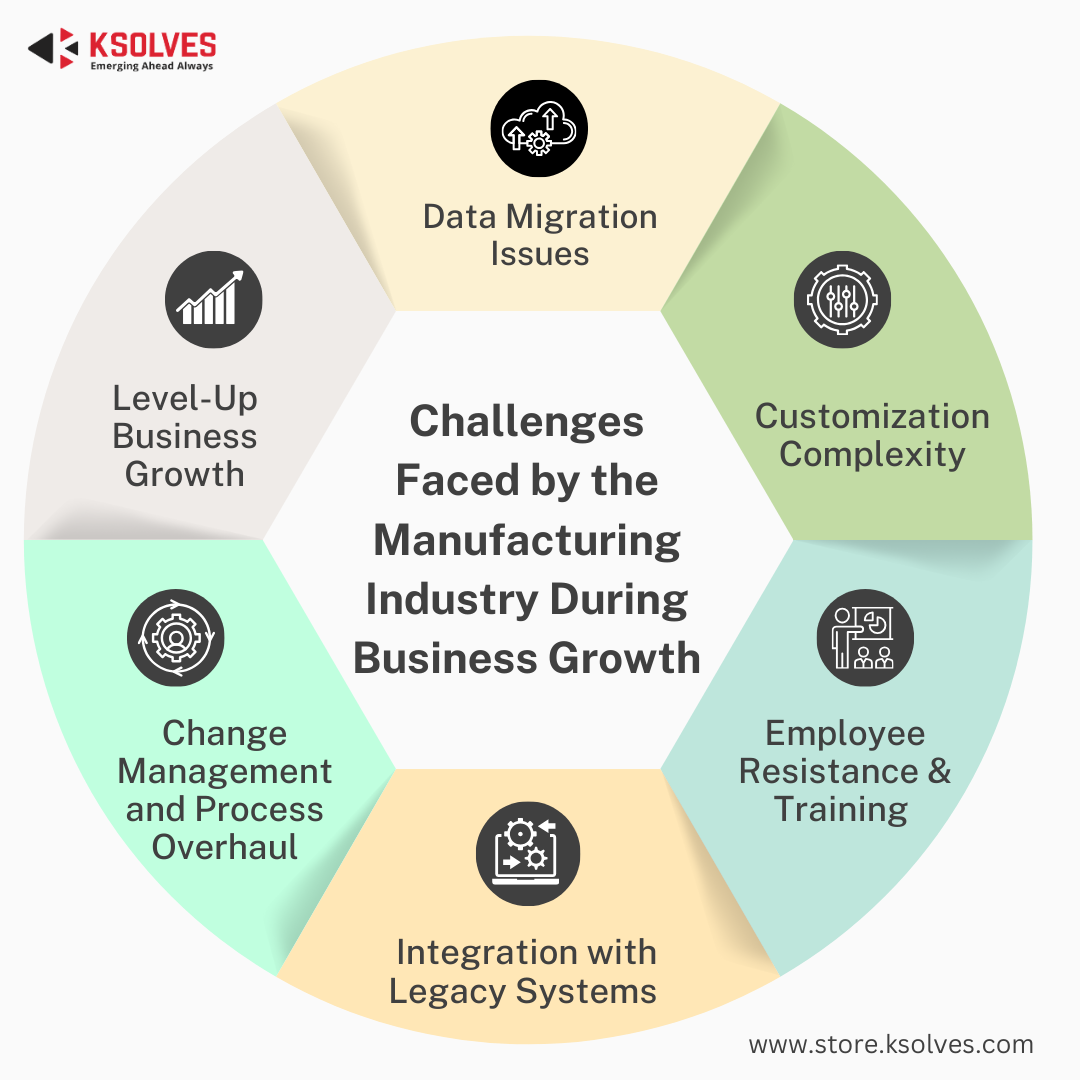

Challenges and Solutions: Implementing Odoo in Manufacturing

When it comes to implementing a new ERP system for an organization like Odoo, you need to face multiple complexities. Those challenges include:

1. Data Migration Issues

Many times implementing Odoo and transferring data into new systems like inventory levels, production schedules, and more leads to data inaccuracies, delays, and BOMs (Bill of Materials) leads to inaccuracies, delays, and disruptions in the production process.

At that time, utilizing Odoo’s data migration tools or hiring professionals experienced in Odoo implementation helps to ensure that the data is transferred accurately. To prevent these issues, regular testing and validation are done during the migration process.

2. Customization Complexity

With a high level of customization in Odoo, it becomes difficult for a manufacturer to tailor the system to their unique business requirements.

At that time, manufacturers start by implementing Odoo’s core modules and then add customizations based on their specific needs and requirements. By consulting with Odoo-certified partners, it is possible to develop custom modules and workflows as per the recommendations. This helps to adapt the Odoo efficiently without overcomplicating the system.

3. Employee Resistance and Training

While implementing new systems and replacing the traditional system or legacy software with Odoo or other ERP systems, employees may face unfamiliar interfaces. This directly disturbs the business workflows and creates operational inefficiencies.

To stay away from this kind of issue, it is important to provide comprehensive training to all the employees who utilize this system. Odoo here, comes as a user-friendly interface that offers specific role training sessions and provides ongoing support for the effortless transition.

4. Integration with Legacy Systems

Many times, manufacturers rely on legacy software or machinery that does not integrate directly with the Odoo system. This lack of integration leads to data inefficiencies, manual data entry, and time delays in the production process.

Odoo, here, comes as the best approach that offers various connectors and APIs and allows integration with other software systems including the legacy platforms. Furthermore, manufacturers must engage with the Odoo experts to develop custom integrations or middleware solutions and ensure smooth data flow between systems.

5. Change Management and Process Overhaul

While implementing an ERP system like Odoo, multiple significant changes have come to establish the business process. The adaptation of production workflows, inventory management practices, and reporting structures to align with Odoo can be overwhelming.

The right implementation of Odoo is the best way to minimize the disruption. Manufacturers should focus on one area of the business at a time such as starting with inventory or procurements and expanding across the world. Clear communication and collaboration must be done to explore the advanced Odoo features.

6. Level-Up For Business Growth

As the manufacturing operations expand, Odoo’s system needs to scale the additional data, users, and production facilities. Poor planning leads to a slowdown of the system or affects the performance.

Utilizing Odoo works as a scalable system but it is a must to plan the business growth accordingly. Manufacturers make sure that their IT infrastructure, including servers and databases, can handle the increased load and audit the regular system performance.

How is Ksolves Odoo Consulting Services Suitable for the Manufacturing Industry?

Ksolves Odoo consulting services are specifically designed for businesses to streamline their operations and boost efficiency. Our experts help the manufacturing industry with its key Odoo modules like Manufacturing (MRP), Inventory, Quality, and Maintenance.

Ksolves helps manufacturers implement Odoo in a way that fits their specific needs. They provide complete support throughout the process, from integrating systems and migrating data to training employees and offering ongoing assistance after implementation. It ensures that manufacturers get the most out of Odoo by tailoring solutions that enhance productivity, reduce costs, and help businesses scale effectively. With their industry knowledge and personalized approach, Ksolves is a reliable partner for manufacturers aiming to optimize their operations.

Conclusion

Odoo is a game-changer for the manufacturing industry, offering scalable and customizable solutions to streamline production, enhance productivity, and improve operational efficiency. Its powerful modules, like MRP, Inventory, and Quality, help businesses optimize workflows, reduce costs, and increase profitability.

With Ksolves’ expert Odoo consulting services, manufacturers can easily implement Odoo, overcome challenges, and tailor the system to their unique needs. Whether improving production or scaling operations, Odoo with Ksolves’ support is the ideal solution for driving growth in the manufacturing sector.

Frequently Asked Questions

1. How Does Odoo Improve Manufacturing Efficiency?

With multiple advanced features or tools present in Odoo, it optimizes the entire manufacturing industry and automates business processes like production planning, inventory management, and quality control.

It improves business efficiency, reduces downtime, and makes sure that proper coordination among team members will lead to reduced business costs and optimize production.

2. What Are the Key Features of Odoo’s Manufacturing Module?

Odoo Manufacturing Module has multiple key features like Material Requirements Planning (MRP), Quality Management, Product Lifecycle Management (PLM), Shop Floor Control, and IoT Integration. These module tools help manufacturers to manage production schedules, inventory, quality checks, and real-time data analytics.

3. Can Odoo Be Customized for Specific Manufacturing Needs?

Yes, Odoo is highly customizable. Its modular structure allows businesses to tailor the platform to meet their unique manufacturing requirements by adding or modifying features and integrating third-party applications as needed.

![]()

AUTHOR

Odoo

Neha Negi, Presales and Business Associate Head at Ksolves is a results-driven ERP consultant with over 8 years of expertise in designing and implementing tailored ERP solutions. She has a proven track record of leading successful projects from concept to completion, driving organizational efficiency and success.

Share with